Blister Packing Machine Operation Manual

1. Overview

- Introduction to the application and functions of blister packing machines.

- Basic machine structure and configuration details.

2. Main Technical Specifications

- Production speed (strokes per minute)

- Compatible materials: PVC, PTP aluminum foil

- Required power supply, air pressure, and machine dimensions

3. Machine Handling and Installation

- Safety tips for transporting the machine

- Site requirements: flat surface, proper ventilation

- Electrical wiring and air connection setup

4. Operation Safety Rules

- Operator qualification and training requirements

- Pre-start safety checks

- Emergency stop procedures and safety protocols

5. Working Principle

- Forming

- Filling

- Sealing

- Batch coding

- Punching

- Output of finished blisters

6. Mould Diagram and Cleaning

- Detailed diagrams of forming and sealing molds

- Mould disassembly and ultrasonic cleaning procedures

- Cleaning frequency and maintenance tips

7. Component Adjustment Guide

- Heating System: Position and temperature control

- Forming Station: Thermoforming (PVC) and cold forming (aluminum)

- Sealing System: Pressure and timing adjustment

- Embossing Station: Batch number depth setup

- Punching Station: Accurate alignment tips

- Material Feeders: PVC and aluminum foil tension control

- Color Mark Sensor: Setup for registered printing (optional)

- Product Filling Station: Volume adjustment (for tablets/capsules)

8. How to Operate the Machine

- Pre-start checklist: Electrical, air pressure, and mold setup

- HMI interface: Touch screen navigation and parameter settings

- Emergency stop: Button location and function

- Trial run: Test run without material

- Start & stop production: Safe production flow

9. Maintenance and Lubrication

- Daily inspection checklist

- Weekly and monthly maintenance tasks

- Lubrication chart and intervals

10. Replacement of Wearing Parts

- List of commonly replaced parts (heating elements, blades, seals)

- Step-by-step replacement instructions

11. Troubleshooting Common Issues

- Electrical issues: Screen errors, sensors not responding

- Mechanical issues: Misalignment, poor forming, sealing problems

- Quick solutions table for fast diagnostics

12. Diagrams and Parts List

- Machine overview diagram

- Lubrication points diagram

- Pneumatic and electrical diagrams

- List of electrical and pneumatic components

- Packing list for shipment

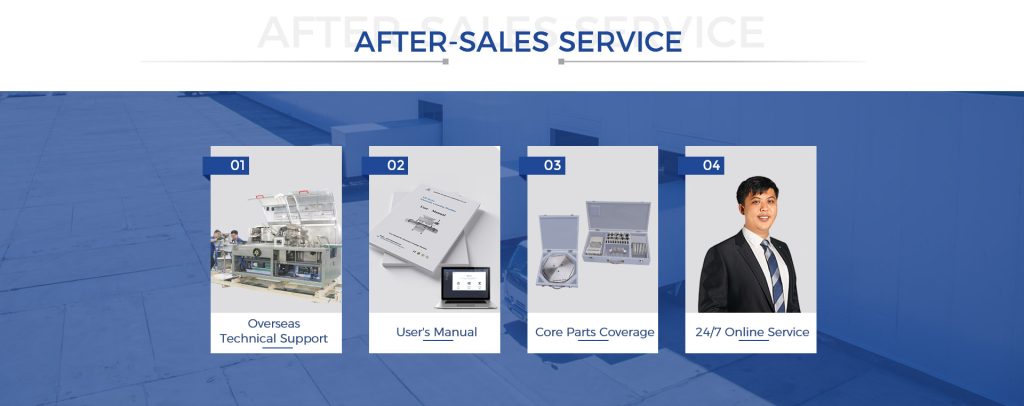

Get the Full Manual and Online Support

Need the complete PDF manual or real-time support for installation and operation?

Contact us today for:

- Full operation manual (PDF format, English/Chinese)

- Installation video tutorials

- Online technical support

- Spare parts ordering

📧 Email: info@finalwe.ru

🌐 Website: www.finalwe.ru

Send Us a Message

Provide overall solutions in packaging and pharmaceuticals.

Contact us and start our cooperation!

Address:

SISP D07, Shenben Street, Hunnan District,Shenyang, Liaoning, China

Phone & WhatsApp No.:+86-188-4239-9929

Email: sales@finalwe.ru